Products

Home > Products > Tungsten carbide for metalworking > Solid Carbide Rods

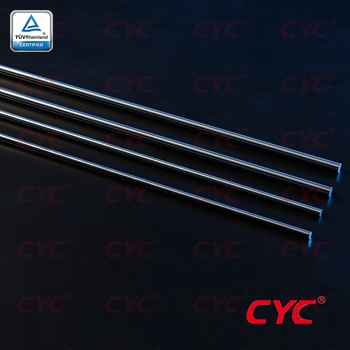

Solid Carbide Rods

We use 100% virgin tungsten carbide material to reach the requirements of good wear resistance and high impact resistance.

Recommended Grade:

MH10F/UH12/UH8/MH7/MH9/SH904

Recommended Grade:

MH10F/UH12/UH8/MH7/MH9/SH904

| Grades | Binder % | Hardness | T.R.S | Density | Grain Size | ISO Code | |

|---|---|---|---|---|---|---|---|

| HRA | HV10 | N/mm2 | g/cm3 | ||||

| MH10F | 10 | 91.8 | 1600 | 3800 | 14.45 | Submicro | K30 |

| An excellent universal grade to cover most of the cuttingapplications for materials of ISO P, M, K, N.Suitable for drilling, milling and reaming. | |||||||

| UH12 | 12 | 92.2 | 1660 | 4000 | 14.15 | Ultrafine | K40 |

| Gives high impact strength while maintaining excellent wear resistance.A universal grade for cutting Stainless Steel,Titanium Alloys, Nickel base alloy and other difficult to machine materials.Suitable for milling, drilling. | |||||||

| MH7 | 6 | 93.1 | 1840 | 2800 | 14.85 | Submicron | K10 |

| A harder grade for machining aluminum alloys, graphite, composite materials.Suitable for milling, reaming and diamond coating. | |||||||

| MH9 | 9 | 92.1 | 1640 | 3800 | 14.5 | Submicron | K20-K30 |

| Achieved ideal balance between wear and impact resistance. Specific suitable for semi-finish and rough machining of Stainless steel, Titanium Alloy, Nickel base alloy like lnconel etc.Suitable for milling, drilling. |

|||||||

| UH8 | 8 | 93.2 | 1860 | 3300 | 14.6 | Ultrafine | K20 |

| Ultrafine grain size offers excellent sharpness for machining hardened materials up to 60 HRC, and extremely high performance machining of non- ferrous metals like Aluminum. Suitable for finish and semi-finish milling, gear hobbing. |

|||||||

| CH03D | 3 | 93.2 | 1860 | 1800 | 15.25 | Fine | K05 |

| Best choice for Diamond Coated Tools. Strongest adhesion and extended tool wear life. Suitable for high performance milling and Drilling of Composites, CFRP,Graphite. | |||||||

1-3 of 3