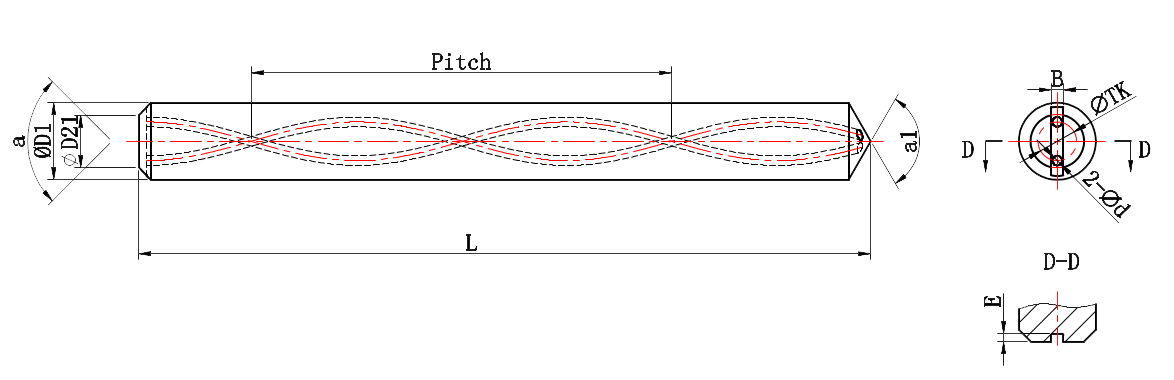

Drill Blank

Advantages & Benefits

- High performance grade for drill application: MH10F

- CYC expertise in the Extrusion forming process, allows a very tight tolerance control of the coolant holes, pcd, and helical pitch, allowing finished Drill blanks available with Hole Depth/Diameter ratios to 40XD.

- Saving your time to cut to length, grinding the od, point and connection slot and increasing your throughput.

Features

- OD both rough and h6 precision grinding are available.

- Point, chamfer and connection slot can be made upon request.

- Standard offering : 3XD, 5XD, 8XD, 12XD, 20XD drill blanks.

New Standard Offering : 20XD drill blanks

| Item No. | OD (mm) |

Tol. h6 (mm) |

L (mm) |

TOL (mm) |

TK (mm) |

TOL (mm) |

d (mm) |

TOL (mm) |

Pitch (mm) |

|---|---|---|---|---|---|---|---|---|---|

| RH20D3-0600-1800PG | 6 | 0/-0.008 | 180 | 0/+1.5 | 2.7 | ±0.2 | 0.8 | ±0.05 | 32.7 |

| RH20D3-0800-2230PG | 8 | 0/-0.009 | 223 | 0/+1.5 | 3.4 | ±0.2 | 1 | ±0.05 | 43.5 |

| RH20D3-1000-2710PG | 10 | 0/-0.009 | 271 | 0/+1.5 | 4.8 | ±0.23< | 1.3 | ±0.05 | 54.4 |

| RH20D3-1200-3230PG | 12 | 0/-0.011 | 323 | 0/+1.5 | 6.3 | ±0.23 | 1.7 | ±0.075 | 65 |

| RH20D3-1400-3670PG | 14 | 0/-0.011 | 367 | 0/+1.5 | 6.7 | ±0.26 | 1.8 | ±0.075 | 76.2 |

| RH20D3-1600-4130PG | 16 | 0/-0.011 | 413 | 0/+1.5 | 8 | ±0.40 | 2 | ±0.075 | 87.1 |

CYC High performance products are guaranteed by a strong process management system, resulting in consistent quality for every batch and product. Strict control of our raw material supply chains and 100% traceability for every product batch throughout the entire manufacturing process. A philosophy of continuous improvements within every process is a core principle in our ways of working. CYC is a ISO 9001:2015(TUV) certified business.