- Solid Carbide Rods

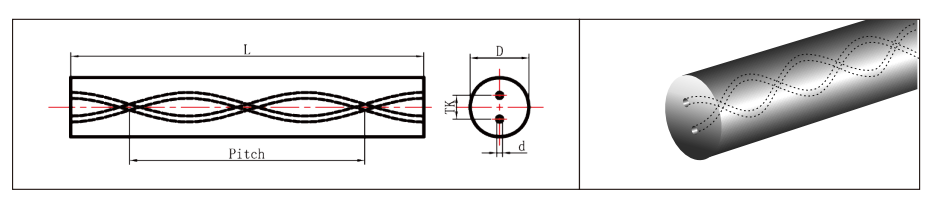

- Rods with Helical Coolant Holes

- Precision Ground Drill Blanks

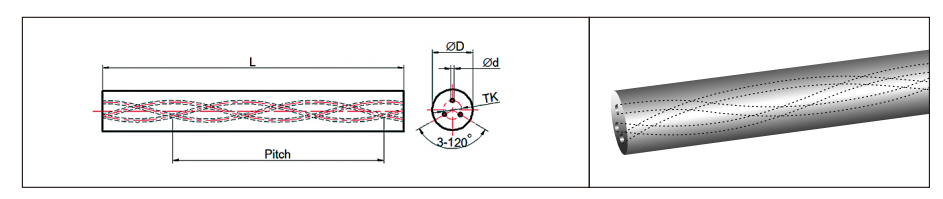

- Rods with Straight Coolant Holes

- TCT Rods for Woodworking

- Indexable inserts

- Profiling Blanks

- Router bits blanks

- Finger Joint tips

- Carbide Strips

- Inserts for Rock Drilling

- Inserts for Coal Mining

- Carbide Balls

- Inserts and Blades for Construction

- Substrates

WHAT ARE YOU LOOKING FOR?