Phone:

86-400-863-2919

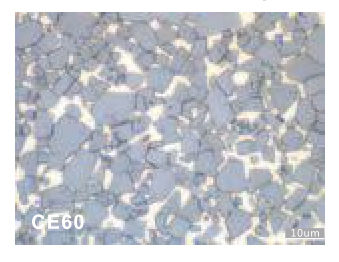

- Solid Carbide Rods

- Rods with Helical Coolant Holes

- Precision Ground Drill Blanks

- Rods with Straight Coolant Holes

- TCT Rods for Woodworking

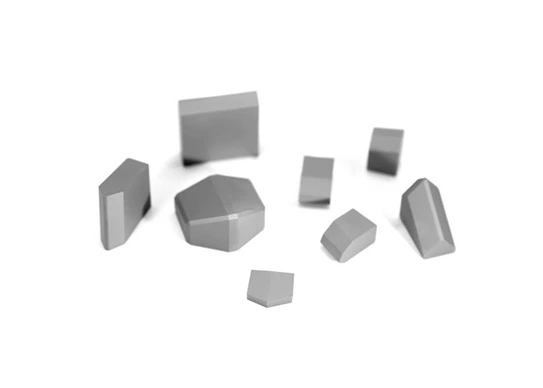

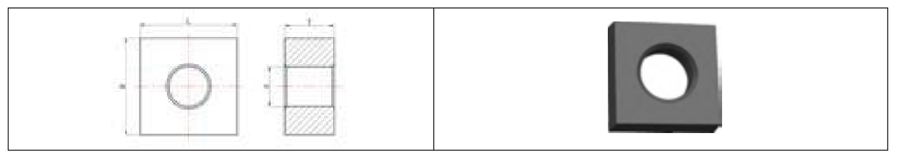

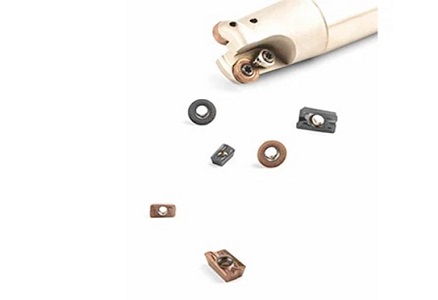

- Indexable inserts

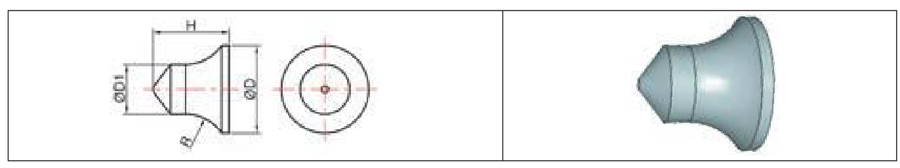

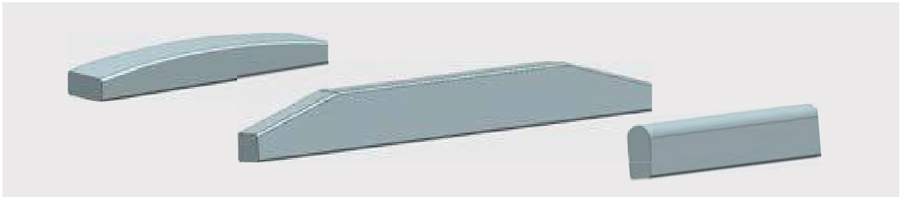

- Profiling Blanks

- Router bits blanks

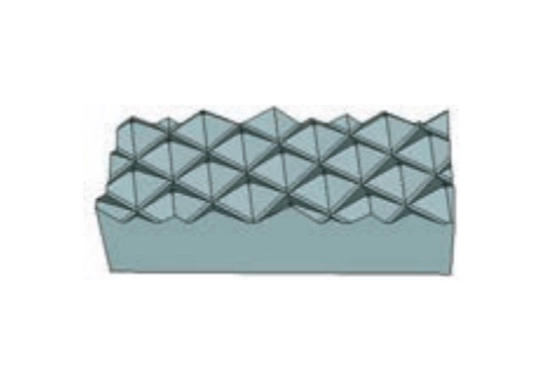

- Finger Joint tips

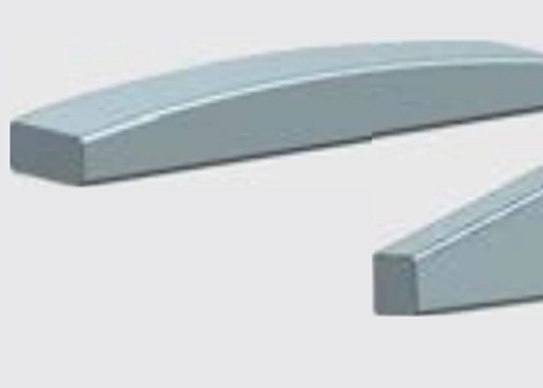

- Carbide Strips

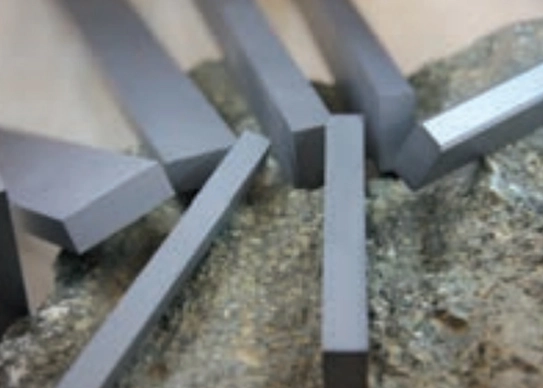

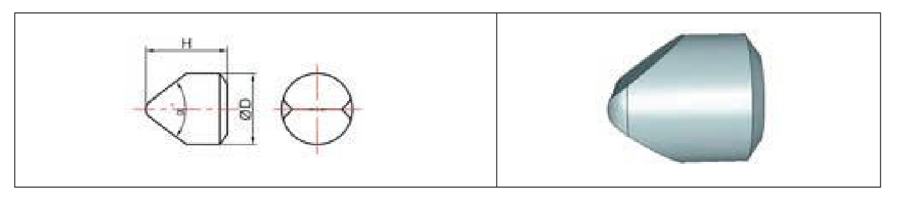

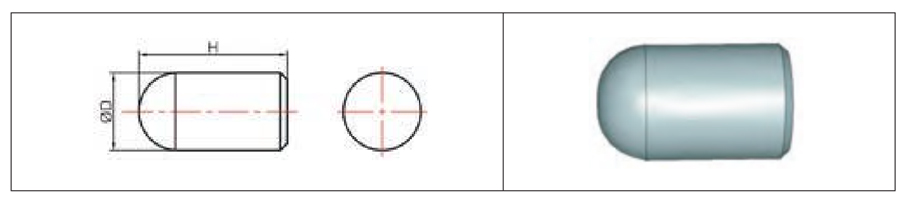

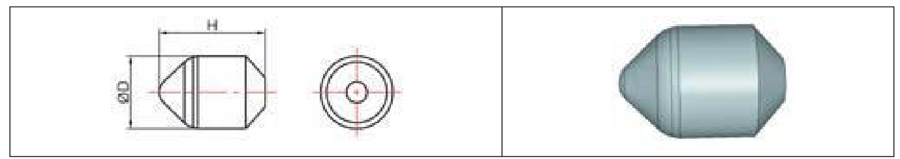

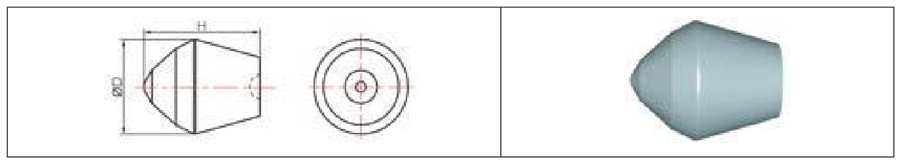

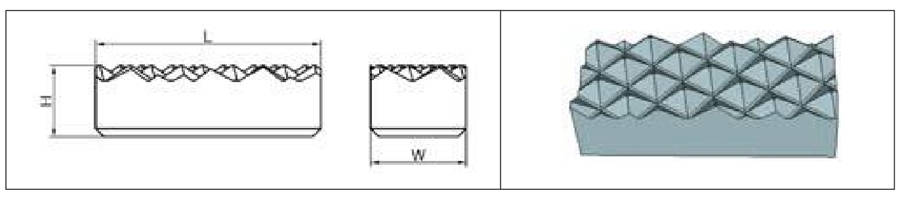

- Inserts for Rock Drilling

- Inserts for Coal Mining

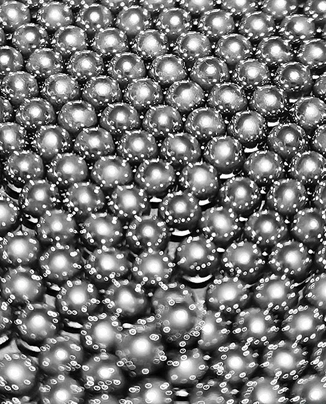

- Carbide Balls

- Inserts and Blades for Construction

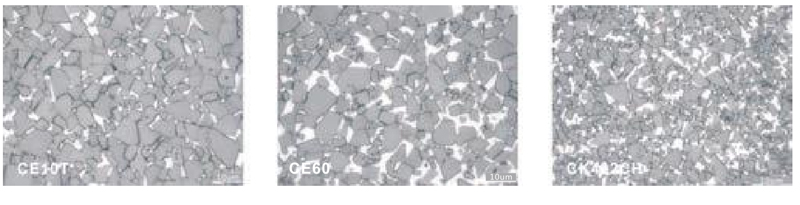

- Substrates

WHAT ARE YOU LOOKING FOR?