Phone:

86-400-863-2919

WHAT ARE YOU LOOKING FOR?

CYC tungsten carbide matrix forms the critical backbone of diamond composite drill bits, engineered for extreme drilling environments. This high-strength carbide skeleton provides essential impact toughness and structural integrity. Precision-controlled carbide grain size and binder phase composition optimize matrix wear resistance and thermal stability under high loads.

Ideal for hard rock drilling, geothermal drilling, and mining applications, this carbide matrix ensures sustained diamond exposure, maximizing bit lifespan and drilling efficiency.

| Grades | Binder % | Grain Size | Density | Hardness | T.R.S | |

| g/cm3 | HRA | HV30 | N/mm2 | |||

| CK401 | 11.5 | Coarse | 14.30 | 87.6 | 1130 | 2800 |

| Suitable for the Substrates of PDC Bits for Oil & Gas Drilling. | ||||||

| CK402T | 15.0 | Coarse | 14.00 | 85.8 | 970 | 2600 |

| Suitable for the Substrates of PDC Bits for Geological Prospecting and Mining. | ||||||

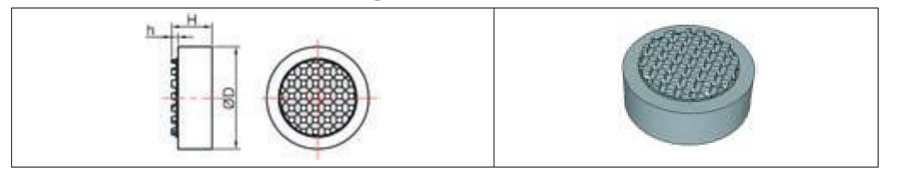

| TYPE | D | H |

| FHR1204 | 12.0 | 4.0 |

| FHR1405 | 14.5 | 5.0 |

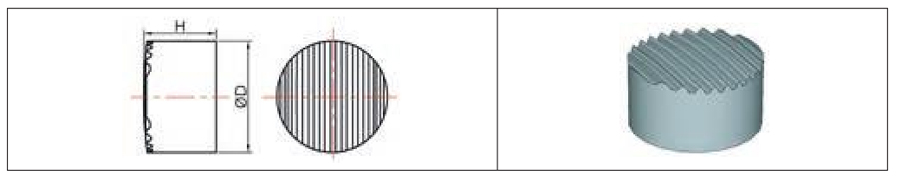

| TYPE | D | H |

| FHO1405 | 14.5 | 5.0 |

| FHO1708 | 17.2 | 8.0 |

| FHO2010 | 20.5 | 10.0 |

Your Success Starts with a Click: Contact Us Now!