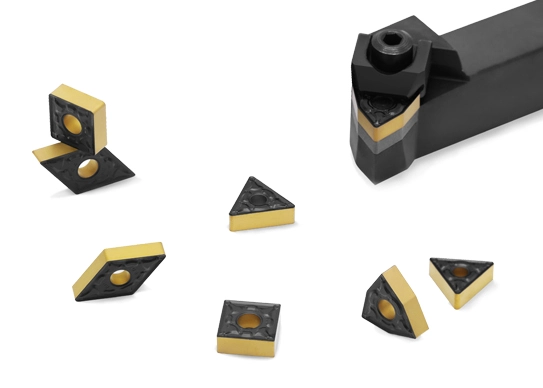

Ceramic grooving inserts are an essential tool for industries requiring high precision, durability, and performance under extreme conditions. Typically used in turning, grooving, and parting applications, ceramic grooving inserts excel in high-speed machining and the processing of difficult materials like hardened steels, high-temperature alloys, and composites. Below are the key features that make ceramic grooving inserts an indispensable part of modern manufacturing.

Superior Wear Resistance of Ceramic Grooving Inserts

One of the primary advantages of ceramic grooving inserts is their exceptional wear resistance. Made from advanced ceramic materials such as alumina (Al₂O₃), these inserts can withstand high temperatures and abrasive conditions without significant wear. This allows them to perform consistently in demanding environments, particularly when machining hard materials such as tool steels, cast irons, and superalloys.

High Thermal Stability of Ceramic Grooving Inserts

Ceramic grooving inserts exhibit superior thermal stability, making them ideal for high-speed machining where high cutting temperatures are inevitable. Unlike carbide inserts, ceramics can maintain their hardness at elevated temperatures, making them suitable for high-heat applications, including machining heat-resistant alloys and materials with a high melting point.

Enhanced Surface Finish and Precision of Ceramic Grooving Inserts

Ceramic grooving inserts contribute to an improved surface finish and precise cuts. Thanks to their high hardness and sharp cutting edges, these inserts can deliver smooth, clean grooves with minimal burrs. This feature is particularly important for industries where surface quality is critical, such as aerospace, automotive, and medical device manufacturing.

Cost-Effectiveness and Tool Life of Ceramic Grooving Inserts

While ceramic grooving inserts may have a higher initial cost compared to other inserts, their long tool life and minimal wear make them a cost-effective choice in the long run. These inserts can be used for extended periods without significant degradation, reducing the need for frequent replacements and downtime during production.

| Feature | Description |

|---|

| Wear Resistance | Exceptional wear resistance for extended tool life |

| Thermal Stability | Can withstand high cutting temperatures without losing hardness |

| Surface Finish | Delivers smooth, high-quality grooves with minimal burrs |

| Tool Life | Long-lasting performance, reducing the need for frequent replacements |

Ceramic grooving inserts offer unmatched performance in challenging machining conditions, particularly in industries that require precision and durability. Their ability to perform at high speeds, resist wear, and maintain sharp cutting edges make the ceramic inserts an essential tool for modern manufacturing processes.