WHAT ARE YOU LOOKING FOR?

CS43 & CS40 are CYC universal-grade carbide solutions with 12% cobalt binder, designed to cover a wide range of machining tasks—from roughing to finishing, and from common steels to difficult-to-machine alloys.

With balanced toughness, wear resistance, and stability, these grades deliver reliable performance across ISO P, M, S and H materials, making them ideal choices for customers seeking versatility, consistency, and cost efficiency in daily production.

Universal Performance

One grade for multiple materials and operations

Suitable for roughing to finishing applications

Optimized Toughness & Wear Resistance

12% cobalt binder for enhanced strength and edge security

Stable cutting under heavy load and intermittent conditions

Proven in Real Cutting Tests

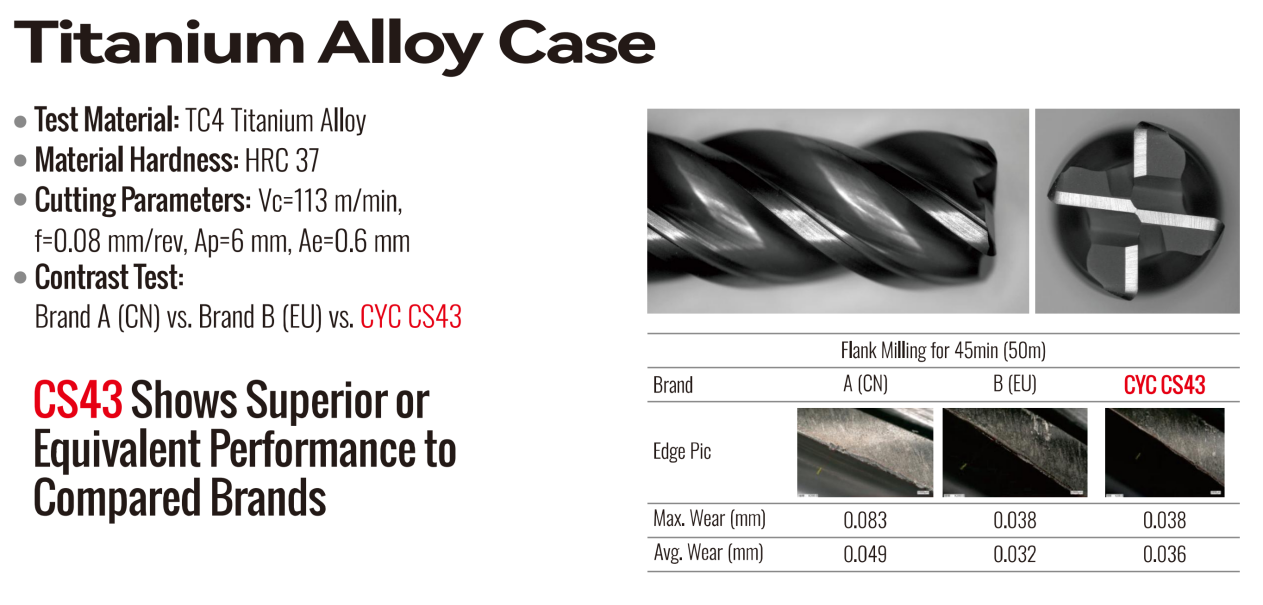

CS43 shows superior or equivalent performance in titanium alloy machining

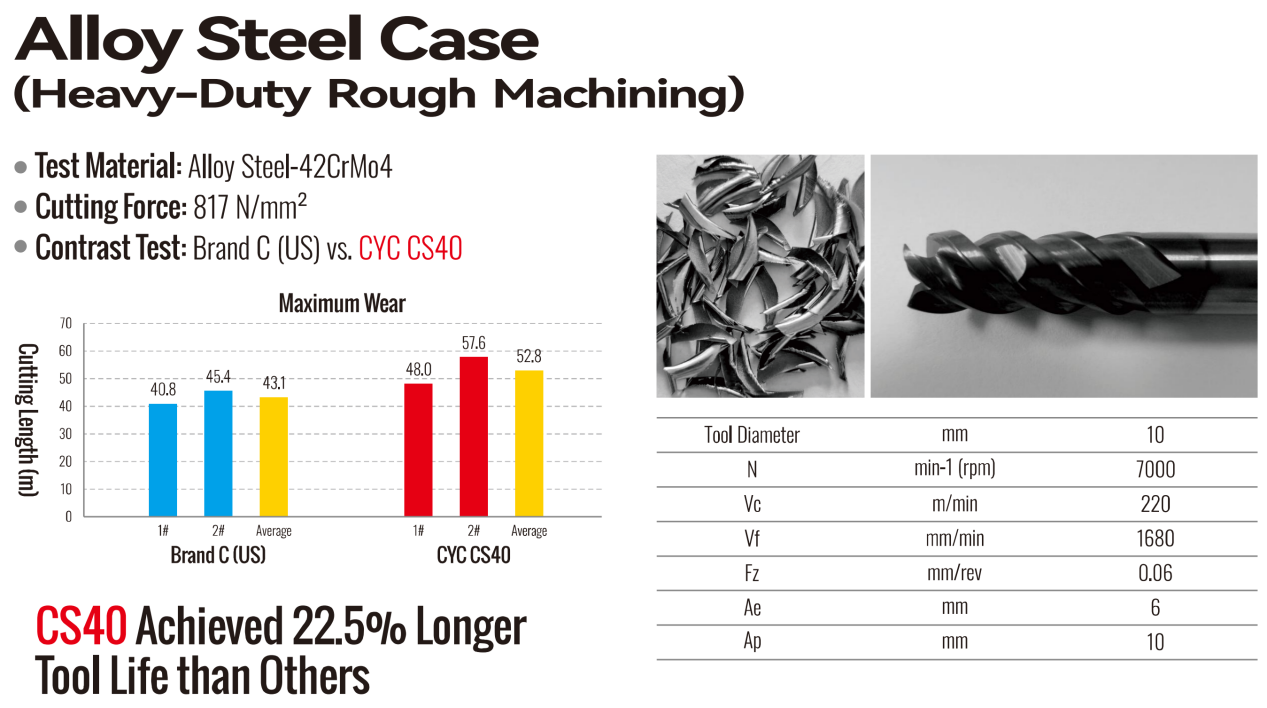

CS40 achieves up to 22.5% longer tool life in heavy-duty alloy steel roughing

Reliable & Cost-Effective Choice

Consistent quality for mass production

Reduced tool changes and lower overall machining cost

| Grades | Binder % | Hard HRA | ness HV10 | T.R.S ≥N/mm² | Density g/cm³ | MPa*m¹/2 | Grain Size | ISO Code | Application |

| CS43 | 12 | 92.5 | 1720 | 4500 | 14.20 | 11.0 | Ultrafine | K40 | High toughness,high wear resistance,suitable for ISO P,M,S,H finishing. |

| CS40 | 12 | 91.5 | 1560 | 4000 | 14.15 | 13.0 | Submicron | K40 | Suitable for roughing and machining under extreme conditions /environments. |

Your Success Starts with a Click: Contact Us Now!