At CY Carbide, we believe that every customer deserves more than a product but a solution tailored to their unique needs. That's why we've built leading custom carbide production lines, giving you the flexibility, control, and performance to turn your ideas into reality.

Carbide Preform Line

Spanning approximately 6,700 square meters and staffed by a professional team of over 160 members, this line serves as the foundation for high-quality carbide production . Its large footprint and skilled workforce enable us to handle both high-volume orders and complex preforming requirements, laying the groundwork for precise, consistent carbide blanks.

Post-Machining Line

Complementing the preforming process, our post-machining line covers nearly 3,000 square meters and is supported by a specialist team of over 50 experts . Focused on refining carbide products to exact specifications, this line leverages specialised skills and equipment to ensure the final product meets the strictest dimensional and performance standards.

Together, these two integrated lines form a single, reliable source for your custom carbide needs, delivering full customisation, rapid turnaround, and uncompromising quality from preforming to final machining.

Customisation at Its Core

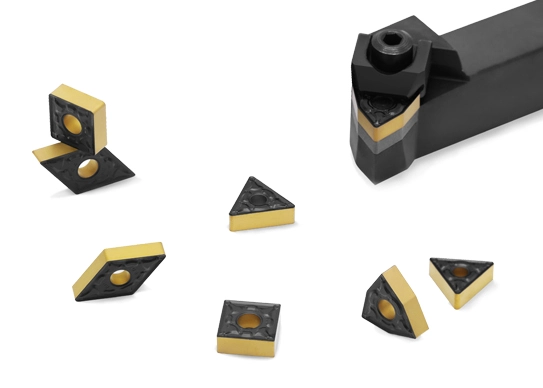

CY Carbide's strength lies not only in its scale but in its deep commitment to customisation. With a team of dedicated materials engineers and tooling specialists, the company partners closely with you to develop tailor-made carbide grades and geometries for specific working conditions, whether in metal cutting, mining, die & mold, woodworking, or construction. Our fully in-house capabilities mean you don't have to settle for off-the-shelf compromises . This customer-first model ensures that you receive solutions that are not only high-performing but also cost-efficient and application-optimised.

You Define the Need. We Deliver the Precision.

CY Carbide's production system is designed to simplify and streamline the manufacturing process for you. From grade design and mold development to precision forming and final machining, every step is engineered to deliver what matters most to you: performance, consistency, and speed to market.

At the core of CY Carbide’s offering is a fully in-house production flow, covering every stage of custom carbide manufacturing:

Carbide grade formulation and powder engineering

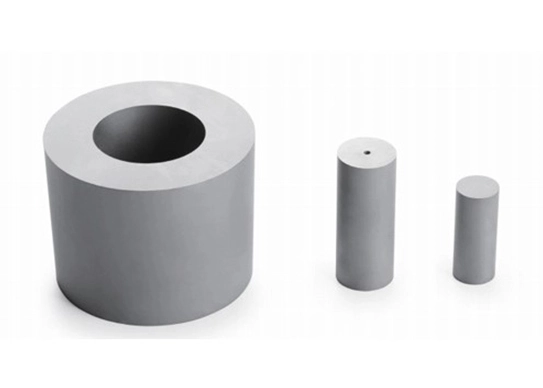

Carbide Preforms:

Maximum Part Length: 450 mm

Internal Diameter: Ø0.5 mm to Ø200 mm

Outer Diameter: Ø1 mm to Ø350 mm

Advanced Forming Processes, including:

Post-sintering Precision Machining:

CNC machining, including internal/external cylindrical grinding, hydrostatic centreless grinding, surface grinding, honing.

This extensive forming and machining capability enables the efficient production of both simple and complex geometries, tailored to specific customer requirements across industries. We maintains complete control over the final performance of each product. This vertical integration translates to better consistency, faster turnaround, and greater value for end users.

Commitment to Quality and Traceability

CY Carbide maintains a rigorous quality assurance process throughout the production lifecycle. All products undergo comprehensive inspection, supported by advanced testing instruments and carried out by a dedicated QC team. The company operates under a TÜV-certified ISO 9001:2015 quality management system, ensuring complete process control and traceability.