Carbide milling inserts are essential tools in modern machining processes, offering exceptional durability, precision, and efficiency. Made primarily from tungsten carbide, these inserts are engineered to withstand the extreme conditions of high-speed and heavy-duty milling operations. Below are the key advantages of using carbide milling inserts.

Superior Hardness and Wear Resistance

Carbide milling inserts possess outstanding hardness, typically rated above HRA 90. This high level of hardness translates into excellent wear resistance, allowing the inserts to maintain cutting performance over prolonged use. They are ideal for machining hard materials such as steel, cast iron, and stainless steel, ensuring a longer tool life and reducing downtime caused by frequent tool changes.

High Performance Under Elevated Temperatures

During high-speed milling operations, cutting temperatures can rise significantly. Carbide milling inserts are designed to retain their hardness and structural integrity even under elevated thermal conditions. Their excellent thermal stability makes them suitable for dry and high-temperature cutting environments, enhancing productivity without compromising tool performance.

Versatile Coatings for Extended Tool Life

To further improve performance, carbide milling inserts often feature advanced coatings such as CVD (Chemical Vapor Deposition) or PVD (Physical Vapor Deposition). These coatings provide additional protection against wear, corrosion, and oxidation. They also help reduce friction and heat generation at the cutting interface, which enhances surface finish and extends the insert's lifespan.

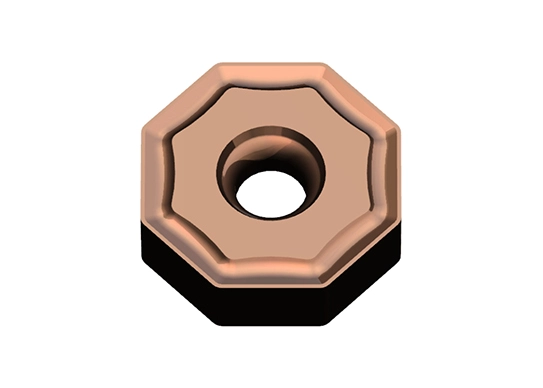

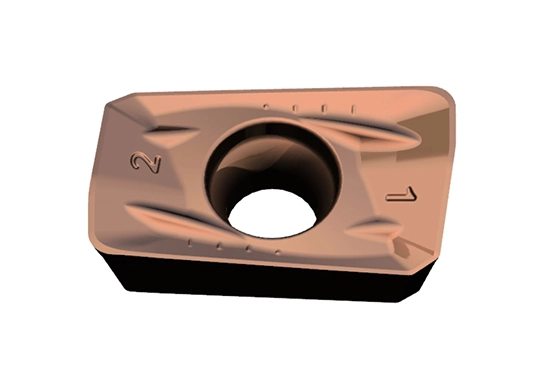

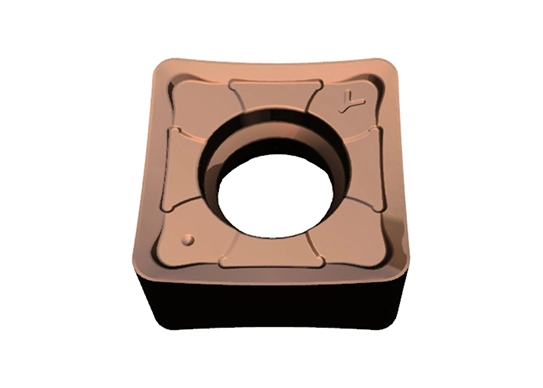

Multiple Grades and Geometries for Various Applications

Carbide milling inserts are available in a wide range of grades, chipbreaker geometries, and shapes. Whether for roughing or finishing operations, users can select inserts that are optimized for specific materials and cutting conditions. This flexibility makes carbide milling inserts suitable for applications across automotive, aerospace, mold making, and general manufacturing industries.

| Feature | Advantage |

|---|---|

| Hardness | HRA > 90 for excellent wear resistance |

| Thermal Stability | Maintains performance at high cutting temperatures |

| Coating Options | CVD/PVD for improved durability and finish |

| Application Versatility | Suitable for roughing, finishing, and more |

In conclusion, carbide milling inserts are a crucial component in achieving high-efficiency, high-precision machining. Their unmatched hardness, heat resistance, and adaptability to different applications make them the preferred choice for manufacturers seeking reliability and cost-effectiveness in their milling operations.