Phone:

86-400-863-2919

- Modular Shanks & Heads

- Special Endmill blanks

- Flat Bars and Discs

- Special Tool Blanks

- Band saw tips for metal

- Bur blanks

- Nibs for Cold heading & Hot Forging Dies

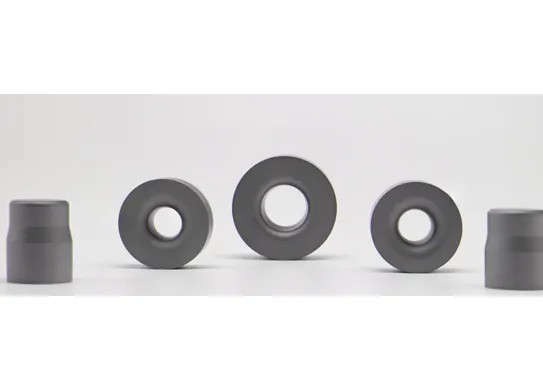

- Powder Compacting Dies

- Preform Blanks

- Battery Drawing Dies / Punches

- Inserts for Rock Drilling

- Studs for HPGR

- Inserts for Coal Mining

- Tungsten Carbide for Agriculture Machinery Wear Parts

WHAT ARE YOU LOOKING FOR?