- Modular Shanks & Heads

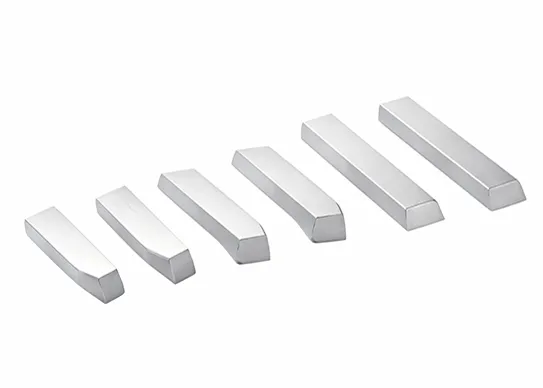

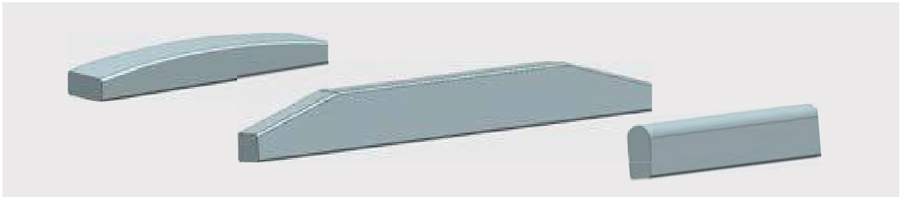

- Special Endmill blanks

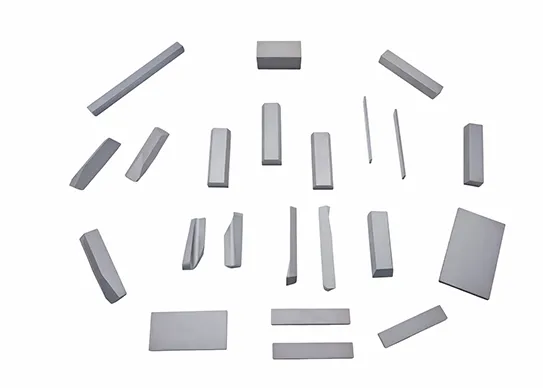

- Flat Bars and Discs

- Special Tool Blanks

- Band saw tips for metal

- Bur blanks

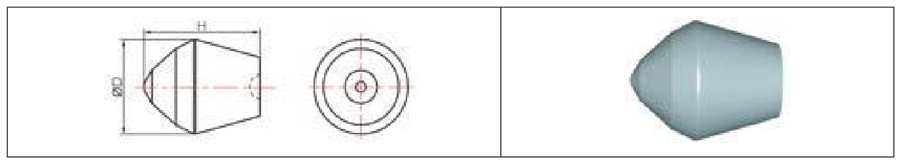

- Nibs for Cold heading & Hot Forging Dies

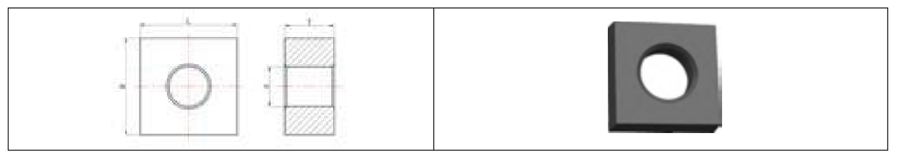

- Powder Compacting Dies

- Preform Blanks

- Battery Drawing Dies / Punches

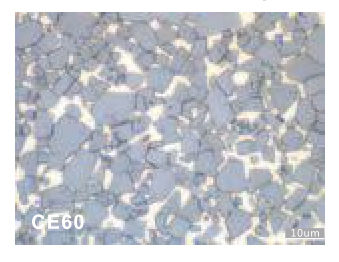

- Inserts for Rock Drilling

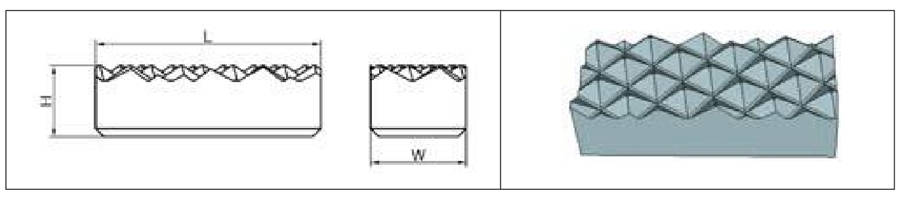

- Studs for HPGR

- Inserts for Coal Mining

- Tungsten Carbide for Agriculture Machinery Wear Parts

WHAT ARE YOU LOOKING FOR?